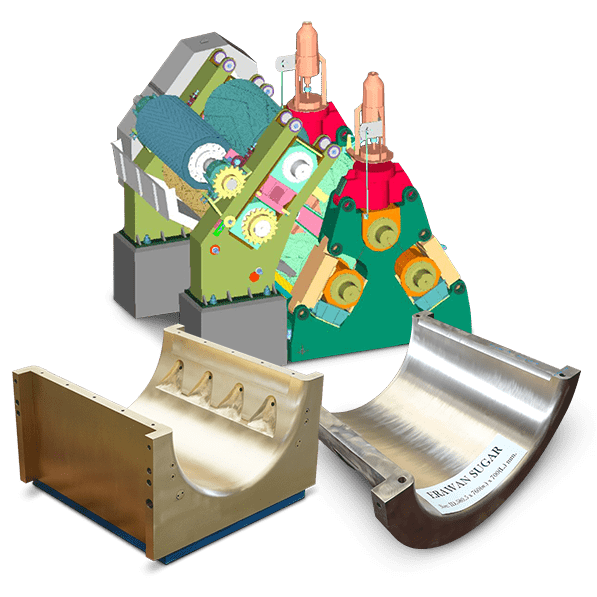

Specialized bearing system with state-of-the-art technology for sugar industry

ABOUT

MillBearings Co., Ltd.

Was established in 2013 to provide all varieties of non ferrous castings, including bronze alloys, pure copper and high content leaded tin bronzes, mainly for the sugar industry

PRODUCT

|

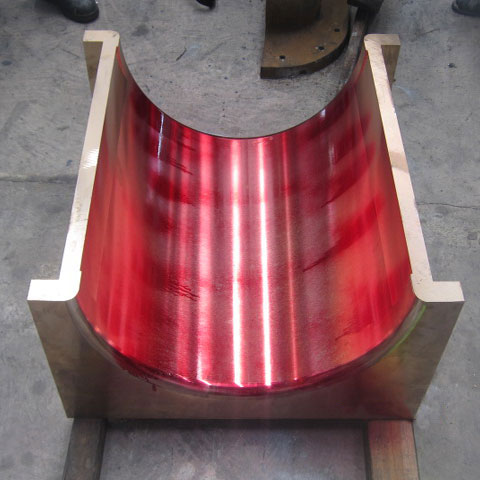

Sugar mill bearing are an important component of the extraction mills, comprising of a hollow casting which must be of the highest manufactured quality, hydraulically sound to ensure that the circulating cooling water is contained within the bearing body. It is essential that the bearing materials used have the requisite properties

|

|

TECHNOLOGY

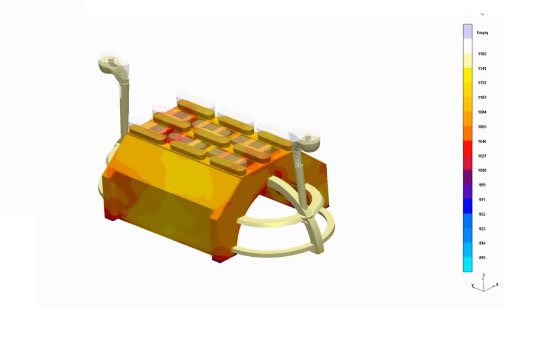

The MillBearings foundry manufacturing these static castings using modern gravity die-casting molds and foundry techniques based upon the most up to date technology using Bronze alloy and Leaded Tin Bronze. Specifically for the sugar industry

Advantages of LBC3 bearings from gravity die-casting process with tilting mold compared to that from sand casting process

- Accurate dimensions

- Smoother casting surfaces

- Higher mechanical properties

- Better tensile strength and hardness due to fine material grain and fine distribution of Pb particles resulting from high cooling rates of metal mold

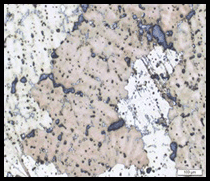

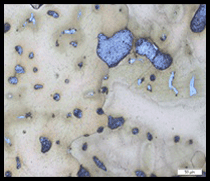

MICROSTRUCTURE ANALYSIS

LBC3 from gravity die casting

LBC3 from sand casting

Distribution of Lead (Pb) particles (dark color) in LBC3 - permanent mold and sand mold casting.

|

HARDNESS TEST RESULT |

||

| From sand casting | From gravity diecasting | |

| HB / 10mm / 1000kgf | 56.8 | 73.9 |

| MPa | 222 | 264 |

|

Benefit of each type of mold |

|||

| Sand Casting | Composite Mold Casting | Die - Casting | |

| Strength | C | B | A |

| Dimensional Accuracy | C | B | A |

| Surface Finish | C | B | A |

| Wear Resistance | C | B | A |

| Cost | A | B | C |

Rating : A - Best to C - the Least

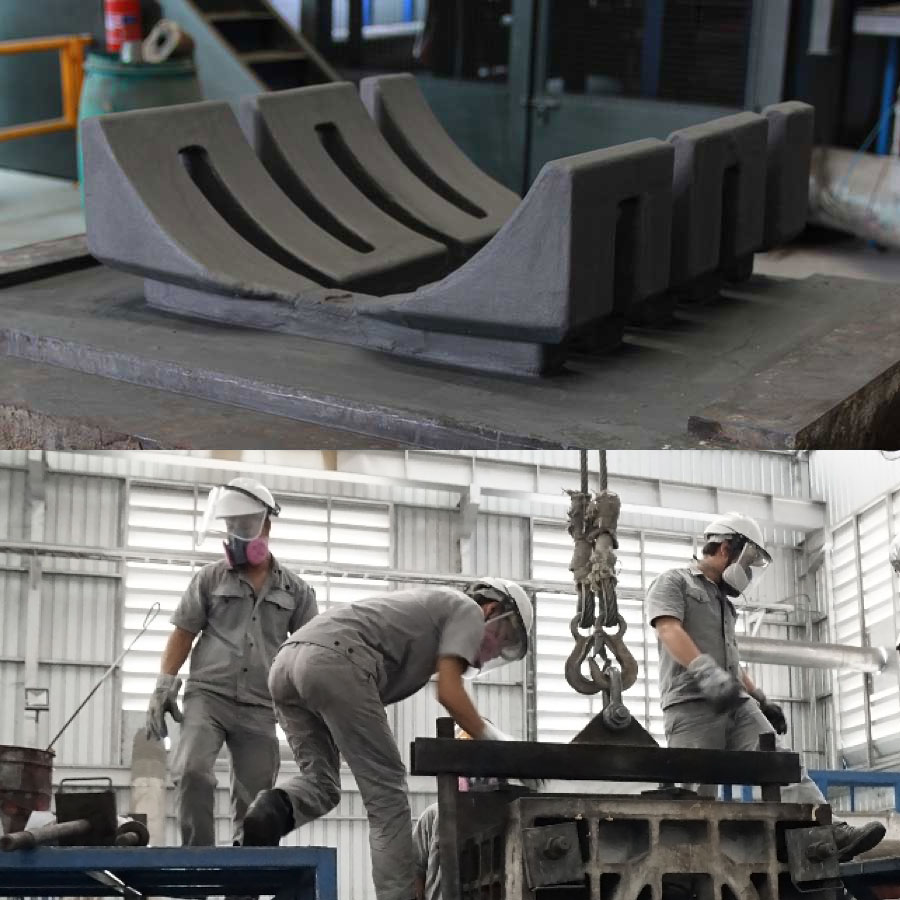

WORKSHOP CAPACITY

LABORATORY

MACHINING

FOUNDRY

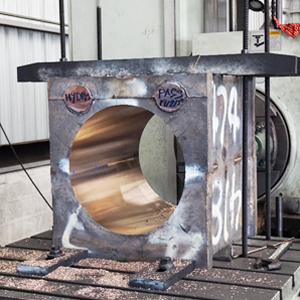

QUALITY CONTROL

PRODUCTS

RESEARCH AND DEVELOPMENT

CONTACT

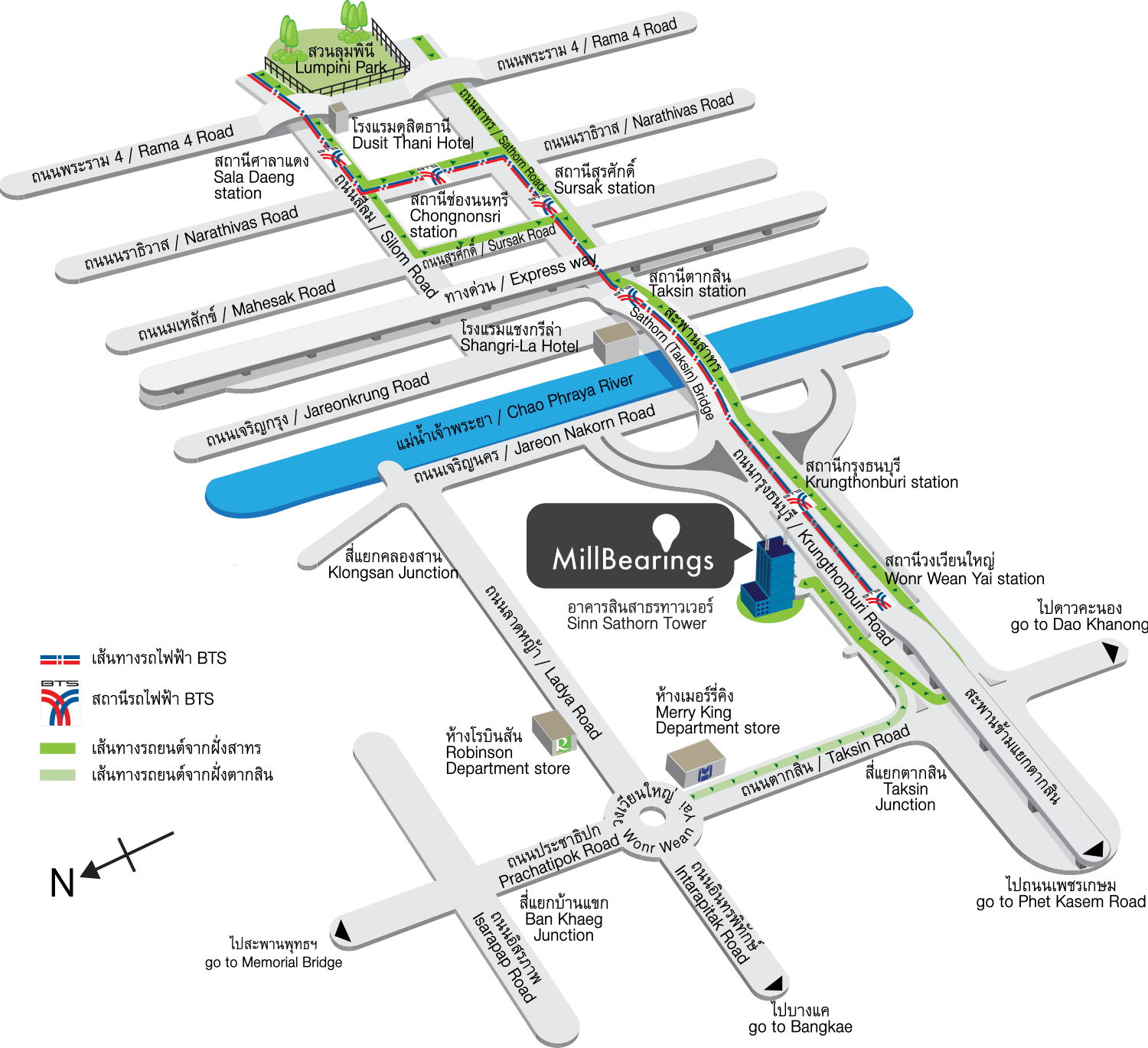

Head Office

77/57 Sinn Sathorn Tower 16th Fl., Krungdhonburi RD., Klongsan, Bangkok 10600 Thailand